mining pumps

Kingda provides slurry pumps and high-performance pumping solutions to global mining.

Focus on pumping different types of mud to extend pump life and reduce costs.

It can produce 10000 sets of slurry pumps, dredging pumps, desulfurization pumps, shield pumps, and other industrial impurity pumps, and 2800 tons of pump accessories. Quality manufacturer for you to choose from!

mining pumps series

KSGH high lift gravel pump

Features of KSGH Series Pumps: Applicable to various mine beneficiation process pumps. Material rubber and iron interchangeable, multiple options.

The operation is stable and reliable, the high-efficiency area runs for a long time, and the energy-saving features are outstanding.

Specially designed for high-concentration and strong abrasive conditions such as mill underflow pump and tailings transfer pump, high efficiency and wear resistance, and optimal LCC life cycle cost.

Detailed parameters:

Pump outlet diameter (mm): 20~750

Flow (m3/h): 10-18000

Head (m): 10~70

KSHF foam slurry pump

Features of KSHF Series Pumps: The super large suction port is matched with the spiral front guard plate to reduce the eddy current of foam slurry at the air inlet and reduce the difficulty of foam entering the pump.

The open impeller design is adopted, and the blades extend to the impeller inlet, which can improve the cavitation performance of the pump, compress and convey the foam, and play a defoaming effect.

The foam volume coefficient can reach 3.0 or even higher, the conveying is stable and reliable, the degree of generalization of parts is high, and the maintenance is convenient.

Detailed parameters:

Pump outlet diameter (mm): 50~ 300

Flow (m3/h): 15~1200

Head (m): 5~65

Efficiency: 80%

ZGB high lift slurry pump

Features of ZGB Series Pumps: The high-lift slurry pump has thicker wear parts and large impeller diameter, suitable for

It is used for conveying the slurry medium with low concentration and high lift or high concentration and low lift;

The pump outlet can be rotated into 8 outlet directions every 45 degrees within 360 degrees,

A multi-stage series connection can be used to meet the requirements of long-distance transportation.

Detailed parameters:

Pump outlet diameter (mm): 65~ 300

Flow (m3/h): 50~1800

Head (m): 50~115

KSG gravel pump

Features of KSG Series Pumps: This series of pumps are single-stage, single-suction, cantilever, horizontal structure. The pump body, the pump cover and the joint plate are connected by a clamp band. It is mainly used for the transportation of strong abrasive materials whose particles are too large to be transported by ordinary slurry pumps. The direction of the outlet of the pump can be in any position of 360°, which has the advantages of convenient installation, good cavitation, and anti-abrasion.

Detailed parameters:

Pump outlet diameter (mm): 100~400

Flow (m3/h): 60~4000

Head (m): 10~60

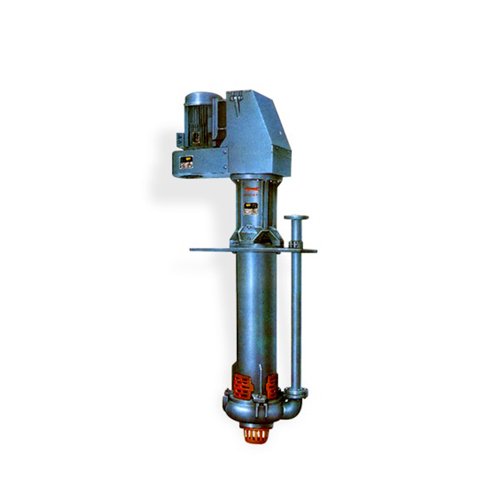

KSS submerged slurry pump

Features of KSS Series Pumps:

Vertical single shell axial suction centrifugal slurry pump

Pit installation, submerged shaft length can be selected

No shaft seal, upper and lower bidirectional feeding

Detailed parameters:

Pump outlet diameter (mm): 40~300

Flow (m3/h): 10-1400

Head (m): 5~35

Mining Pump and Control Solutions

Wear-resistant

All of our mining pump flow parts are made of A05 material, A05 is a very wear-resistant metal.

Large particle treatment

We manufacture mining pumps in several series that can easily transport slurry containing abrasive solid large particles.

Various driving methods

Our mining pump drive modes are divided into four transmission modes: CV, CRZ, CLZ, and ZVZ, which are not limited by usage scenarios.

High temperature resistance

It is very distressing that the equipment generates high temperature. Don’t worry, we have anti-high temperature grease on our equipment, which can effectively solve the problem of high temperature.

Selection reference

Conveying large particle media

When the particles are large or the corrugations are sharp, you can choose high-chromium wear-resistant alloy parts such as KB04 and KB07 instead of rubber.

Conveying mud medium

The KSL series mining pump is an excellent choice for transporting low concentration and medium abrasive media. It can work very efficiently and reduce maintenance costs at the same time.

Conveying corrosive media

ZGB series is high head corrosion resistant type of mining pump, suitable for conveying low concentration media, can be used in series with multiple stages,low maintenance cost

State-of-the-art production equipment

kingda has 378 sets of main production equipment and 73 sets of special equipment. It has the production capacity of the whole manufacturing chain from model manufacturing, casting, heat treatment, machining, sheet welding, rubber lining, assembly, testing, etc.

At the same time, it also has high and low pressure pump stations. Before leaving the factory, each pump needs to go through strict experimental tests before it can be put on the market. Ensure product quality.

Have More Questions Please Contact Us

The Ultimate Guide to Mining Pumps

kingda Pump is a large comprehensive pump company integrating research, design and manufacture of slurry pumps, submersible pumps, desulphurisation pumps, sewage pumps, chemical pumps and more.

You get a pump that is cast, finely ground and finished, assembled and tested from Kingda’s own factory.

Kingda pumps are very competitively priced on the international market.

If you want to buy a slurry pump, you can send a message to us, and we will give you a systematic price according to the model, head, flow, etc. you need

Of course, we will send you a detailed product introduction by email. If you have any questions, you can contact us at any time.

We will have engineers to match the appropriate motor according to your pump needs, which can ensure that your pump runs more efficiently

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right pump you want.