Kingda pump group

KSL Light Slurry Pump

Kingda® KSL light slurry pump is cantilevered, horizontal, centrifugal slurry pumps.

KSL light slurry pump operates at high speed with small volumes to save floor area, and is suitable for delivering low-density slurries for metallurgical mining, coal, and building material departments.

KSL

light Slurry Pump

Overview

KSL light slurry pump is a slurry pump specially designed by Kingda Pump Group for low-concentration slurry transportation.

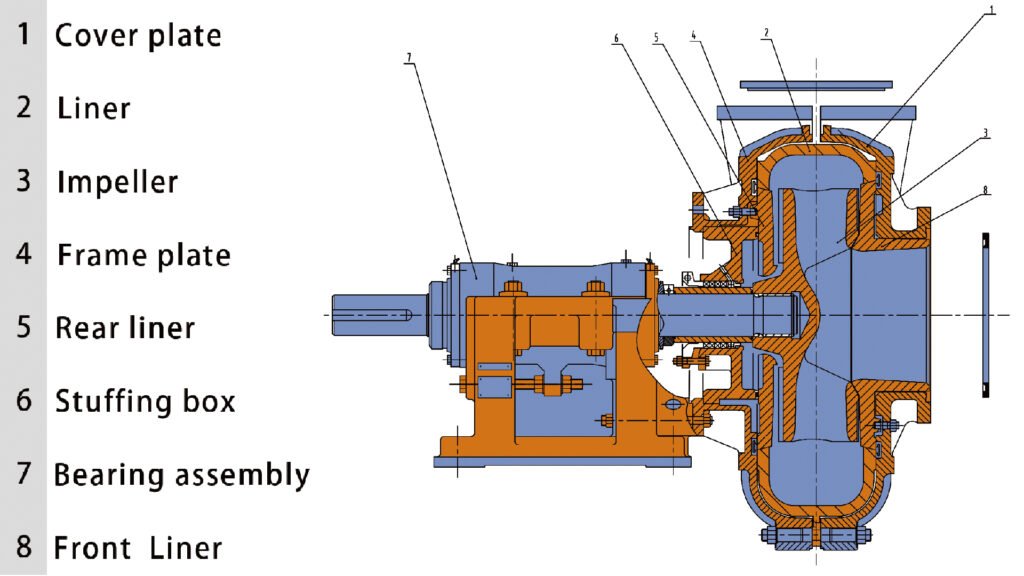

The shaft seal adopts a gland seal, centrifugal seal, and mechanical seal. KSL is smaller in size, saving floor space for better installation.

The frame plates have changeable, wear-resistant metal liners or rubber liners and the impellers are made of wear-resistant metal or rubber.

The KSL series has the characteristics of high wear resistance and corrosion resistance, and can work efficiently in harsh industrial and mining conditions while ensuring wear life, thereby prolonging the service life.

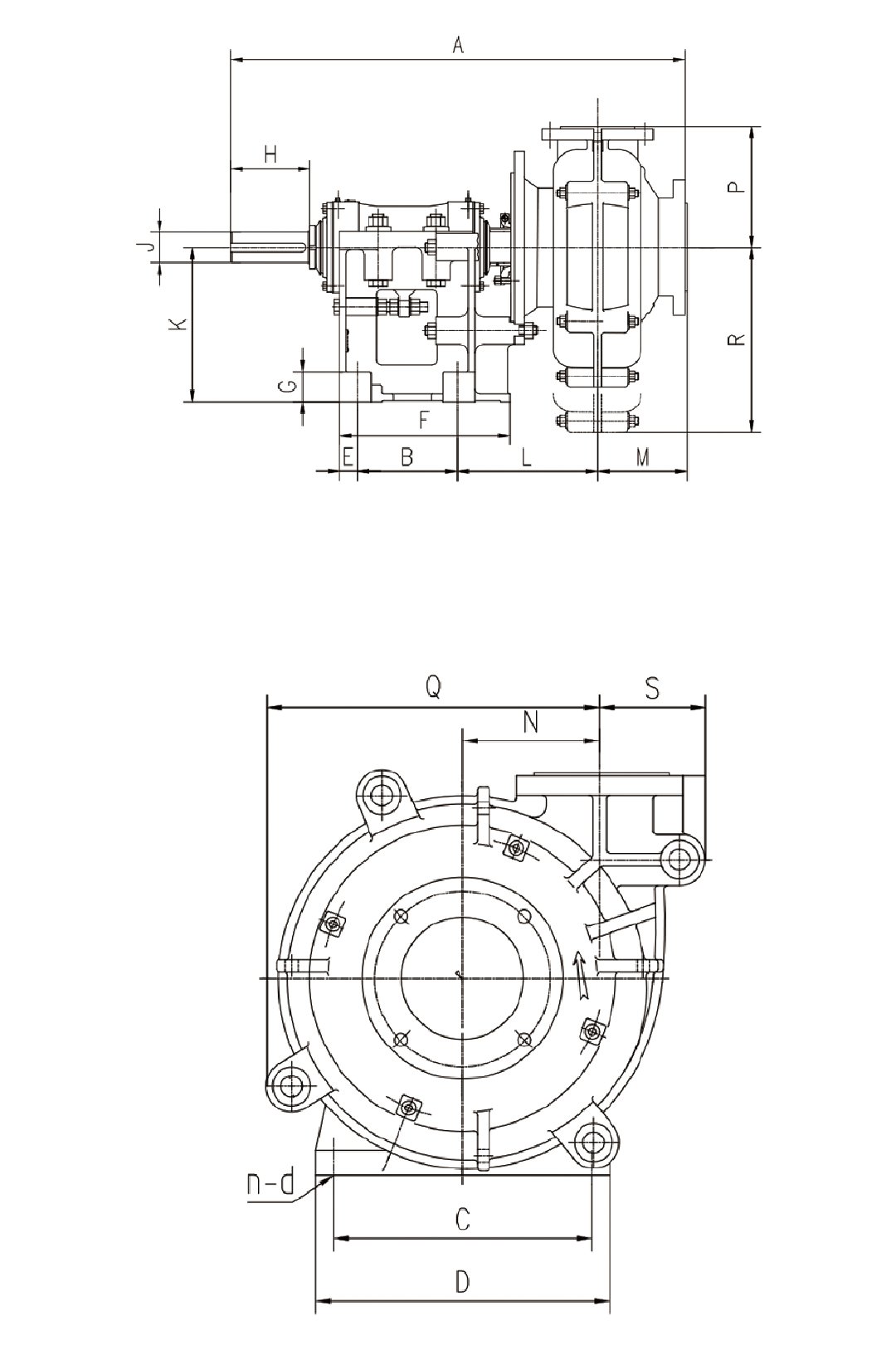

Product Parameters

| Specifications | |

|---|---|

| Discharge Diameter(mm) | 20~650 |

| Flow Rate(m3/h) | 10~14000 |

| Head(m) | 10~60 |

| Material: | Alloy Wear-resistant Material/Rubber |

Performance Range

KSL

Working Range of KSL Light Slurry Pump

(only for preliminary selection)

features and benefits

Strong conveying capacity

KSL light slurry pumps can handle low-abrasive, low-concentration slurries, including ore slurry, coal gangue slurry, sludge, etc. They are specially designed with higher speed and smaller size.

Excellent wear resistance

The pump body, impeller, and other key components are usually made of wear-resistant alloy materials or rubber materials, which can effectively prolong the service life of the pump and reduce the frequency of maintenance and replacement parts.

High efficiency and low energy consumption

KSL light slurry pump usually have efficient hydraulic design and optimized impeller shape to provide the best pump efficiency. This means that when handling slurries, the pumps can generate greater delivery capacity with less energy consumption, reducing operating costs.

Reliable and stable performance

KSL light slurry pump has been carefully designed and tested and has good reliability and stability. They are capable of continuous operation in harsh working environments and are able to cope with different operating conditions such as changes in flow and head.

Application

KSL light slurry pump transports mud, sand, lime slurry, ash, and other substances in the fields of mining, metallurgy, coal, electric power, chemical industry, and environmental protection, and plays an important role in various technological processes in many industries.

KSL light slurry pump has the characteristics of high wear resistance and corrosion resistance and can work efficiently in harsh industrial and mining conditions while ensuring wear life, thereby prolonging the service life.

KSL light slurry pump have the advantages of high efficiency, wear resistance, adjustable outlet direction, reliable sealing system, and automatic lubrication system, which can efficiently process and transport low-concentration slag.

KSL light slurry pump stands out for its advanced design, exceptional performance, and robust construction, making it a reliable choice for handling challenging industrial slurry applications.

Spare parts

Metal Parts

Made of high chromium alloy and other durable materials, it boasts exceptional wear resistance, good impact resistance, the ability to withstand higher pressure and harsh conditions, high-temperature resistance, and impressive mechanical strength.

Rubber Parts

Rubber spare parts offer excellent corrosion resistance for use in chemical and mining industries, good wear resistance for low to medium wear slurry transportation, elasticity to absorb impact energy, and are cost-effective with relatively low manufacturing costs.

Frequently Asked Questions

How To Choose A Slurry Pump

When it comes to slurry pumps, you might think that all you need is a pump that can handle the job. But if you’re not careful, you could end up with a pump that’s not only ineffective but also dangerous and expensive.

There are a few important things to consider when choosing a slurry pump: design, construction materials, deployment method, pump seal, and power seal.

Slurry Pump Design

When selecting a pump, you don’t want to end up not getting the right one suitable to get the job done. So, you might need to ask yourself: how big is your slurry?

The size of your slurry is a huge factor in determining what kind of pump you need. If the slurry is small, you could probably use an open centrifugal pump or a closed impeller pump. However, if you have a large amount of slurry that needs to be pumped, then you’ll need to look into a centrifugal axial pump or even a double-suction centrifugal pump.

Slurry pumps come in all shapes and sizes—round, rectangular, square, even triangular! You’ll want to find one that fits your needs perfectly. If you’re going to be transporting your slurry through narrow pipes, you may want one with a smaller diameter opening. If you need to move your slurry quickly, look for one with a large capacity and high flow rate.

Next up: how much does it weigh? This is especially important if you plan on transporting your slurry by hand or with a forklift. The heavier the better if that’s going to be part of your workflow!

And finally: what kind of environment are you working in? If you’re working outdoors (or even indoors), you’ll want something that can withstand both extremes of temperature and weather conditions like rain or snowfall without breaking down on you or corroding over time due to exposure to air pollution like car exhaust fumes.

Construction Materials

Choosing a slurry pump is a lot like choosing a partner for life. You need to know what you want, and you need to be able to compromise with your partner.

The construction materials of the slurry pump can have a significant impact on its performance. The material used in the construction of the pump should be resistant to wear and tear, so that it can be reused for long periods of time.

When choosing a slurry pump, there are many factors to consider. Here are a few of the most important ones:

- Construction materials

Slurry pumps can be made of cast iron, stainless steel, and other metals. Cast iron is more durable than stainless steel and will last longer, but it is heavier than stainless steel. Stainless steel is lighter and easier to install than cast iron, but it is not as durable over time.

- Durability

Durable slurry pumps will last longer than less durable models, so you should consider this factor when choosing your pump.

- Capacity

The capacity of your slurry pump should match the size of your tank so that you don’t overload it or run out of water too quickly during use!

Slurries are specialized compounds found in various processing industries, including sanitary sectors like mining, aggregates, mineral processing, dredging, tunneling, and water treatment, as well as other industries that involve slurry or sewage. Because slurries combine the properties of liquids and solids, special consideration must be given when determining the type and size of the slurry pump to use with them. Kingda Pump features several companies that specialize in slurry pumps capable of handling a wide range of loads, from light to heavy.

SLURRY PUMPS ARE?

Slurries are solid-liquid mixtures, with the liquid acting as a transport mechanism for the solid. The size of particles in slurries can range from a micron to thousands of millimeters. The ability of a pump to move a slurry through a process line is greatly influenced by particle size.

A slurry pump is a centrifugal pump used to transport abrasive and frequently corrosive solid particles inside a carrier fluid. To minimize substantial particle velocity and thus wear rates, the slurry pump should have a low specific speed design that allows for slower operating speeds than ordinary water pumps. Depending on the application, wear-resistant metallic or elastomeric materials are used in slurry pump components that come into contact with the pumped medium.

All Slurries Share Five Essential Characteristics:

- Abrasive when compared to pure liquids.

- Thicker in texture than pure liquids.

- Many solids may be present (determined by a percentage of total volume).

- When the slurry is not moving, the solid particles usually settle out of the residue relatively quickly (depending on the particle size).

- Moving slurries require more energy than moving pure liquids.

Slurries are further classified into four classes by industry based on their aggressiveness, with Class 1 being the least aggressive and Class 4 being the most aggressive. Pumping slurries can wear out pumps and pipeline components in the following ways:

- Gouging, high-stress grinding, and low-stress grinding are abrasions (applicable only with settling-type slurries).

- Surface material resulting from the actions of particles that make up the slurry that is pumped is known as erosion. Pumping settling-type slurries cause the most decay.

- Corrosion is caused by electrical galvanic action in the pumped fluid. Specific slurries (highly acidic or alkaline compounds) have a more significant impact on component corrosion than others.

What Is A Slurry Dewatering Pump?

A slurry dewatering pump is used to pump liquid with solid particles. Submersible slurry pumps vary in design and construction to accommodate different kinds of slurry that differ in saturation solubility, particle density, physical properties, and solvent content. Submersible slurry pumps are more durable than liquid pumps because they have ritual sacrifice content and substitutable wear parts to endure abrasion wear.

The percentage and layout of impellers in the propeller affect efficiency. When handling slurries, efficiency savings are generally undermined by authorizations and the requirement to build abrasion-resistant heavy-duty components while considering materials, thickness, and other factors.

Types Of Slurry Dewatering Pump

Submersible Slurry Pump

These powerful electric submersible pumps are used to pump sand and mud in dredging, quarrying, and mining industries. All models are wear-resistant materials and come standard with an agitator to dissolve solids under water.

A submersible pump has a significant role because it pushes water to the surface by converting rotational energy into kinetic energy into pressure energy. This is achieved as the water enters the pump: first at the inlet, where the rotation happens of the impeller pushes the water through the diffuser.

A submersible pump’s primary and only benefit is that it will never need to be primed because it is submerged in the liquid. It is also very efficient as they don’t need much energy to get or pour water, which will get to the pump.

Only the pressure forces water into a submersible pump, which “saves” a lot by preventing some leakage.

Also, while the pumps aren’t versatile, the choice certainly is. Other submersible pumps can easily handle solids, while others are better suited to liquids. Submersible pumps are quiet because they are submerged, and cavitation is never a problem as there are no ‘pressure spikes’ as the water flows through the pump.

Centrifugal Slurry Pump

Centrifugal pumps in quarries come in solids or slurry handling and clean or dirty water handling. The pump design for these two applications varies greatly. Therefore the operating performance is also different, resulting in significant differences in the power required for the pumps to function correctly.

A slurry pump, in general, is a troublesome iron pump with open clearances, a heavy duty architecture, and minimal machining in its manufacture. As such, those pumps are appropriate for pumping massive or vast quantities of solids contained in slurries. Dredging/slurry pumps, along with Warman or Metso (cease suction) and Dragflow/Toyo (submersible), are top examples of those sorts of pumps in which hydraulic performance isn’t as essential as their capacity to deal with rocks, sand, ore, and different solids-encumbered fluids without experiencing immoderate put on or downtime, even as working in very trying situations for prolonged periods.

What Is A Slurry Pump?

Pumps designed specifically for handling slurry are called slurry pumps. Slurry pumps are more sturdy and heavy-duty than water pumps, which are more susceptible to wear. Slurry pumps are used when there are particles in the fluid stream. Application-based pump and material decisions should be made for trouble-free performance when handling highly corrosive or abrasive liquids. Lindquist lists several businesses that are experts in manufacturing slurry pumps that can take a range of slurry loads from low to heavy.

A slurry pump is a type of centrifugal pump used to move solid particles inside a carrier fluid that is typically acidic and abrasive. To reduce solid particle velocity, the slurry pump should have a low specific speed design that enables slower operating speeds than typical water pumps.

Features Of Slurry Pumps

As indicated below, many different pumps are appropriate for pumping slurries. Before selecting a technology, there are a few crucial considerations to make. The amount of physical wear on the pump and its parts, as well as whether or not the solids will pass through the pump without being affected, will depend on the size and type of the particles in the liquid.

Slurry pumps are often more significant, influential, and made with stronger shafts and bearings than regular pumps. The most common kind of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, much like a centrifugal pump would move a liquid that resembles water.

Slurry-optimized centrifugal pumps frequently have the following characteristics in addition to the standard features:

- Increased size and material content of the impellers. To account for abrasive slurry wear, this is done.

- Less and thicker vanes are present on the impeller. Unlike a typical centrifugal pump, which has 5–9 vanes, its 2–5 vanes allow solids to pass through it more readily.

For pumping abrasive slurries, these pumps can also be made of specialized high-wear alloys such as AL-6XN® or Hastelloy® C-22®. Two hardening methods frequently used to harden stainless steel for abrasive slurries are armory and expensive.

Positive displacement pumps may be preferable to centrifugal pumps for some slurry pumping applications. Some of the ailments include:

- An excessively sluggish slurry flow rate

- Someone with a big head (i.e., the height to which the pump can move liquid)

- Higher efficiency is required than can be provided by centrifugal pumps.

- Control over flow has been enhanced.

Slurry Pump

Components

Motor

It could be hydraulic or electric. The submersible electric slurry pump needs to be maintained cool. A cooling jacket should be added if the slurry pump is semi-submerged or dry for an extended period. A motor with Class H insulation is advised for heavy-duty electric slurry submersible pumps. They may also have sensors that recognize high temperatures and moisture.

Impeller

The rotating part of the slurry pump is the impeller. The slurry receives the centrifugal force. They are usually made of spheroidal cast iron with high chromium, which is abrasion-resistant. Impellers can be closed, open, semi-open, or recessed.

Casing

Typically, the casing has a semi-volute or concentric shape. Although it is frequently made of cast iron, depending on the application, it might also be coated to avoid corrosion or made of specialized alloys for abrasive applications.

Shaft And Bearing Assembly

The shaft is in charge of conveying the impeller’s rotating motion from the motor. The shaft’s heavy-duty roller bearings reduce vibration by preventing it from moving in other directions.

Shaft Sleeve

Keeping the shaft secure is its duty. A corrosion- and abrasion-resistant material makes up the shaft sleeve.

Seals Package

The seals’ package stops slurry from leaking into the motor and bearings. The sealed container may contain lip, mechanical, and hybrid seals.

Upper And Lower Plates

The impeller has these plates on both sides. They are susceptible to degeneration. The pump’s clearances are calibrated to maximum efficiency.

Strainer

The filter stops large particles from becoming trapped inside the pump’s impeller zone.

Agitator

This enables the pump to suspend solids while capturing sediments. The way it operates is that the vanes direct a constant, high-pressure flow of liquid in the form of a cone toward the deposits, moving the solids there and generating a high concentration. Additionally, the agitator prevents particles from clogging the pores of the filter.