Peristaltic Slurry Pump

Leading manufacturing technology amidst an increasing technological market competition.

- Reliable

- Innovative

- Adaptive to technological changes.

- World Class

What is Peristaltic Slurry Pump?

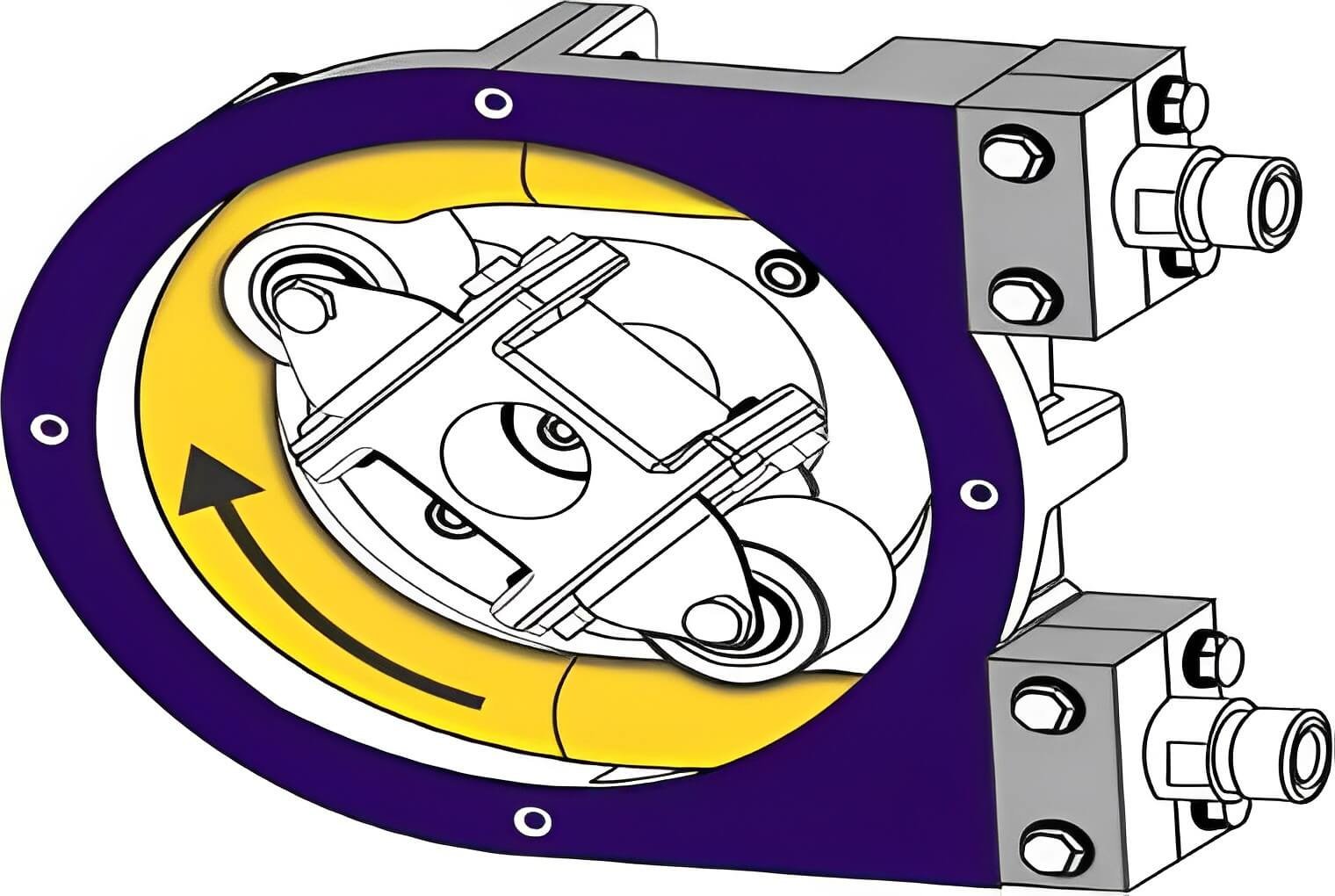

Positive displacement is the principle behind how peristaltic pumps, commonly known as hose or tube pumps, operate. Rollers that spin squeeze a flexible tube against the pump housing to feed fluid through the tubing. Since the pump comes into touch with the fluid, peristaltic pumps are perfect for use with corrosive and viscous fluids. The pumps are practically maintenance-free and reasonably affordable to maintain because the tubing or the head is simply replaceable. Therefore, peristaltic pumps used in industry and medicine are among the most widely used tube pumps.

Different Peristaltic Slurry Pump Types

Polyvinyl Chloride Peristaltic Slurry Pumps

PVC tubing is non-toxic laboratory grade, and it is especially resistant to inorganic compounds like bleach, diluted sulfuric acid, and nitric acid. When tube cost is a primary consideration, this tubing performs best in short-term, continuous pumping applications.

Silicone Peristaltic Slurry Pumps

Silicone Peristaltic Slurry Pumps is a flexible, peroxide-cured medical-grade tubing that offers good resistance to temperature fluctuations. The tubing is soft and flexible, and there are no plasticizers within that could leach out and taint the flow. Tasteless, odorless, and inert, it is ideal for use in both continuous and intermittent peristaltic pump applications.

Thermoplastic Rubber Peristaltic Slurry Pumps

Thermoplastic Rubber Peristaltic Slurry Pumps is a high purity grade TPE compound that is used to create clear flexible tubing. MD65-TPE has a high level of clarity, kink resistance, clamp resilience, and performance traits that are comparable to PVC, in contrast to most TPE materials. It is perfect for short-term peristaltic pump applications because it does not include DEHP or phthalate plasticizers.

Viton Rubber Peristaltic Slurry Pumps

It provides exceptional resistance to lubricants, fuels, oils, and the majority of mineral acids. In addition, it is resistant to aliphatic and aromatic hydrocarbons (carbon tetrachloride, benzene, toluene, & xylene). Highly corrosive acids may be transported.

PharMed Peristaltic Slurry Pump

PharMed Peristaltic Slurry Pump is a beige-colored, opaque thermoplastic elastomer (TPE) made of polypropylene. It complies with United States Pharmacopeia Class VI specifications and maintains its flexibility and stability between -40 and 135 °C.

Fluoropolymer Peristaltic Slurry Pump

The remarkable heat resistance of fluoropolymer material—up to 500°F continuously—is well known. Its efficacy in really cold conditions is less well recognized. Up to -100°F, it will still be quite flexible. The application of fluoropolymers for corrosion prevention has grown to be one of their major growth areas since they are virtually always inert to industrial chemicals and solvents.

Product Advantages

Peristaltic Slurry Pumps: Use Less Water

Due to this restriction, slurry pumps have significant process water requirements. For example, on a plant processing 75t of ore per hour at 65% solids, switching from a process slurry pump to a hose pump annually saves more than 1,100 million liters of water.

Peristaltic Slurry Pumps: Less Power

Many established mines are concerned about power rationing, and for new ventures, the infrastructure costs to import power can be high, even result in significant delays, and spark a lot of resistance from non-mining environmental groups.

Peristaltic Slurry Pumps: Less Environment Impact

Cyanide-based leaching methods are frequently used in mineral recovery procedures, particularly when gold is a valuable commodity. Cyanide has various harmful effects on the environment, including poisoning the area around the facility, aquifers, and the aquatic life in waterways.

peristaltic slurry pumps: less harmful to the environment.

Mineral recovery processes typically employ cyanide-based leaching techniques, particularly when gold is a significant commodity. Cyanide poisons the land around the facility, aquifers, and aquatic life in streams, among other negative consequences on the ecosystem.

Peristaltic Pumps Market: Market Dynamics

The global expansion of this market is anticipated to be fueled by the rising demand for peristaltic pumps in the global pharmaceutical industry. Pharmaceutical items, biological and medical products, and the isolation of active medicinal ingredients in the manufacture of herbal medicines and plants all frequently use peristaltic pumps.

Peristaltic Slurry Pumps Market: Regions

Based on regional analysis, the peristaltic pumps market is divided into five key regions. The Peristaltic Pumps Market in Asia Pacific held the greatest market share of XX.X% in 2018 and is anticipated to maintain its market dominance going forward. These regions include North America, Latin America, Europe, APAC, and MENA. Europe and North America are expected to grow significantly during the forecast period as a result of the rising pharmaceutical and food and beverage sectors in these regions.

Peristaltic Slurry Pumps Market: Segments

The market for peristaltic pumps is predicted to grow significantly, with a CAGR of 6.5%, by 2030.Market for Peristaltic Pumps expected to reach USD 2.03 billion in 2030, up from USD 1.02 billion in 2018, at a CAGR of 6.5% from 2019 to 2030. In the coming years, there will be a major increase in demand for peristaltic pumps due to rising knowledge of the maintenance cost savings and operating performance.

Benefits of the Kingda Pump

To achieve product upgrades, scientific research institutions in universities are continuously increasing their investment in the development of new technologies and products. Since the advent of industrialization, Kingda has been one of the distinguished manufacturers in China and has been recognized abroad for its top quality product and world-class designs.

Useful Function For Using Our Pumps

Duty cycle

When choosing a pump, it is crucial to take the duty cycle into account. Reduced speed is required if the pump is required to run continuously for extended periods of time (hours on end). The performance curves provided by reputable manufacturers will specify which portion of the pump curve can be used on a continuous basis and which portion should only be utilized on an intermittent basis

Flow

The majority of performance curves are based on flooding suction and materials that resemble water. While working with more viscous fluids or high suction lifts, it is necessary to take these factors into account when sizing the pump for the right flow, including de-rating speeds for these elements. Good manufacturers will have de-rating charts for higher viscosity.

Pressure

Peristaltic pumps come in several varieties. Pumps can be used in applications with pressures up to 15 bar thanks to superior designs. This is made possible by hoses rated for these pressures as well as rollers, rotors, and other parts made to withstand such high pressures. The models that are rated for these pressures as well as the flow and speed restrictions will be specified by the manufacturers.

Suction Condition

Peristaltic pumps are capable of producing significant suction lifts, however any chosen for a task requiring a suction lift should be equipped with a pulsation dampener. Additionally, the diameter of the suction line should be increased if the viscosity is higher than 2000cPs. Keeping the suction line as short as possible is another helpful “rule of thumb.”

One Stop Best Slurry Pump Solution

The first factory in China to produce slurry pumps, sewage pumps, and submersible sewage pumps is Kingda, which was established in 1949. Get a hundred patents now. One-stop service, scheme design, product planning, product installation, and post-service are all things we offer.

our service

To assist you in resolving any issues, Kingda offers round-the-clock support. We offer online coaching. In addition, we replace parts using a variety of payment options (Prepaid 30% available).

Have More Questions Please Contact Us

Bottom FAQ

Positive displacement is the principle behind how peristaltic pumps, commonly known as hose or tube pumps, operate. Rollers that spin squeeze a flexible tube against the pump housing to feed fluid through the tubing. The tubing expands as the roller passes over it, creating a vacuum that lets more fluid in.

Peristaltic pumps get their name from the way that food and liquids move through people and animals, a process known as peristalsis.

Typically, clean/sterile or highly reactive fluids are pumped using peristaltic pumps to prevent contamination of those fluids from exposed pump components.

They are most frequently utilized to transport sterile or harsh chemical fluids. Additionally, they are able to pump IV fluids or slurries with a high fluid content. During surgery, they are also used for heart and lung machines.

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right pump you want.