In the slurry pump market, there are many slurry pump manufacturers, and the price of slurry pumps is also varied, some are tens of thousands and some are only a few thousand dollars. What causes such a huge gap, and how can buyers make the right choice? Here, I will briefly explain several factors that affect the price of the slurry pump, so that you can better understand how the money should be spent.

First, slurry pump selection: the model of the slurry pump determines the price positioning of the slurry pump.

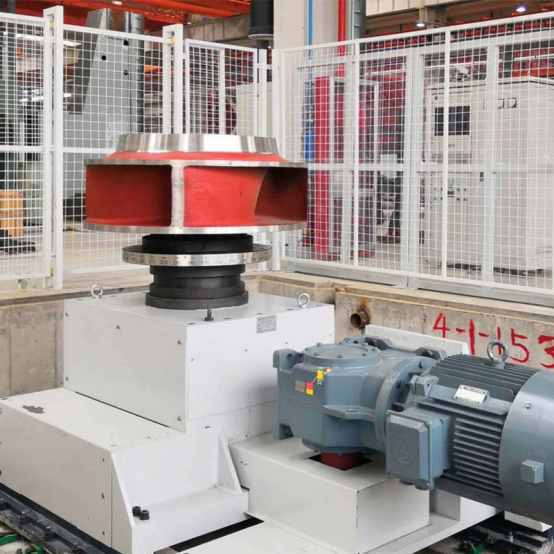

According to the industrial and mining conditions, there are many kinds of slurry pumps that can be selected. For example, When AH horizontal slurry pumps can also be selected, namely Warman slurry pumps, ZGB heavy-duty slurry pumps can also be selected. , but the price difference between the two pumps is very obvious. The price order is ZGB>AH. Among them, the AH Warman slurry pump is a kind of slurry pump introduced from the Australian Pump Factory. Its performance is stable and reliable, but its selection range is wide, it is easy to cause power waste, and the efficiency is average; the ZGB type heavy-duty slurry pump is redesigned by Kingda group on the basis of the Warman slurry pump. The ZGB slurry pump weighs more than the AH. It is much heavier and more materials are used. The design of ZGB allows as long as the impeller, guard plate and casing are not worn out, it can be work normally, the lift and flow can be kept stable all the time, which is enough to show the excellence of this kind of pump. In addition, the design efficiency of the ZGB heavy-duty slurry pump is relatively high, and the power used is adjusted and selected according to the concentration of the medium. Therefore, the ZGB slurry pump is also the most expensive but now more and more commonly used in the industries for less down time, Most coal washing plants use this type of pump now, and price is also downing some due to this trend. The price of the AH Warman slurry pump is the most Inexpensive, because the AH Warman slurry pump has a long history, the pump structure is stable and fixed, many costs can be saved.

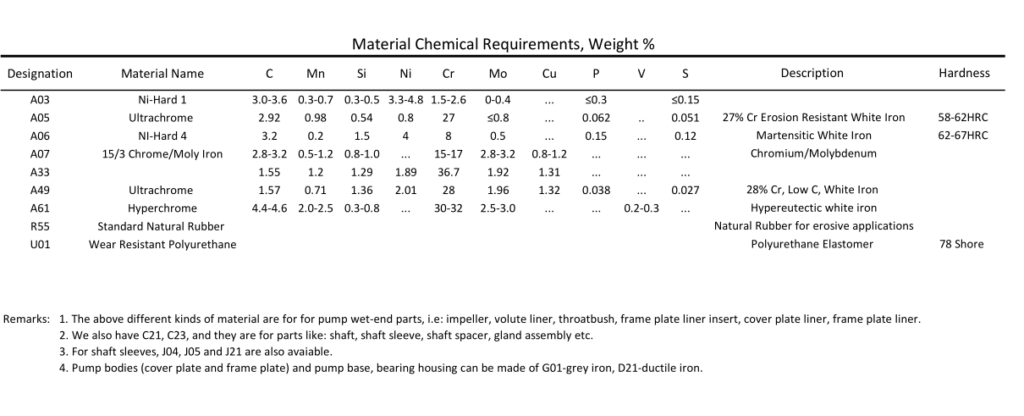

Second, the material of the slurry pump accessories determines the price of the slurry pump.

The most expensive parts of the slurry pump are the wearing (end-wet) parts, namely: casing, frame and rear plates, and impeller. Usually, the slurry pump is made of high-chromium wear-resistant alloy KmTbCr26, which is also used by most manufacturers , as long as this material is selected, the basic price will not fluctuate too much, because the cost is fixed, but many manufacturers have reduced the element content in the material list to become Cr20 or lower, and the content of nickel in it is very little or no. In addition, the shaft sleeve and disassembly ring, which should have been made of 3Cr13 material, are then 45# steel material, which will also reduce the price a lot; Normally the main shaft production should have been normalized, but one less process will also reduce costs, Some manufacturers use this way. In other words, for small factories various methods have been used to reduce costs, so as to compete for the first place in the prices, which has also caused the chaos and various prices of the slurry pump market.

Third, the weight of the slurry pump accessories determines the price of the slurry pump.

The design weight of the wearing parts (Casing, frame and rear guard plates, impeller) in the slurry pump accessories is determined based on comprehensive considerations such as the service cycle. In order to reduce the cost, many small factories will deliberately reduce the size of the mold. The original 100kg thing has become 80kg or even lower. The cost of the slurry pump accessories is calculated based on the weight of the materials and the processing fee. If the weight is reduced, the price can be much less, and the price of the whole pump can be reduced even more. , but the service life is shortened a lot,and then more problems and down time will come.

Fourth, the processing technology and assembly technology of the slurry pump accessories are also factors that determine the price of the slurry pump.

Slurry pump accessories are a relatively high-precision process. Many manufacturers fail to meet the accuracy of accessories due to manufacturing equipment or other reasons. Although it does not affect the looking it may appear during first use. Lots of bugs will come to you soon. In addition, the assembly and debugging of the slurry pump is very critical. The dynamic balance and static balance testing of the slurry pump accessories, as well as the assembly and testing of the slurry pump, should be relatively strict, requiring a lot of technicians and tools to achieve qualified products. However, many small factories save this part or even no this part in order to save time or money, so as to obtain more profits, which is also one of the factors that affect the price of slurry pumps.

To sum up, there are too many factors that determine the price of slurry pumps, and it is impossible to list them one by one. I only hope that buyers will not blindly consider manufacturers from the perspective of price. They must know the principle that you get what you pay for. After all, i want to say, choose Kingda we will not let you down, feel free to let me know your any questions.