Industrial and mining slurry pumps

Kingda has been developing for 73 years to provide the highest quality technology and services to help you be more productive and profitable in your mining, dredging, desulfurization operations.

- Advantage: Sustainable pumping solutions

- Advantage: Cone crushers for modern process

- Advantage: Revolutionising mill lining rubber

- Advantage:Making mining more sustainable

Features of slurry pump

The slurry pump is divided into M, AH and HH type pumps which are cantilever and horizontal centrifugal slurry pumps. They are suitable for conveying strong abrasive and high concentration slurries in mining, metallurgy, coal, electric power, construction and other industrial sectors. This type of pump can also be used in multiple stages in series.

The pump body of M and AH pumps has replaceable wear-resistant metal lining or rubber lining, and the impeller is made of wear-resistant metal or rubber material. The pump body lining and impeller of HH pump are made of wear-resistant metal.

The shaft seal of M, AH and HH pumps can be packing seal or centrifugal seal. The outlet position of the pump can be installed and used at eight different angles at 45-degree intervals as required.

Slurry Pumps Details

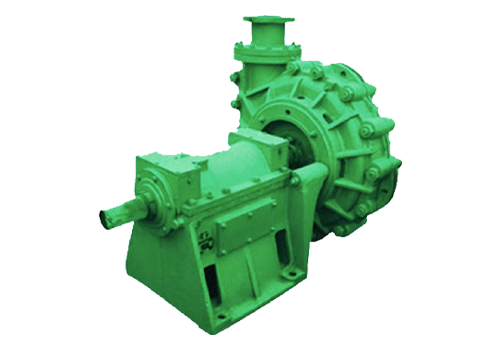

KSH series heavy-duty slurry pump

KSH type pump is a cantilever, horizontal centrifugal slurry pump. It is suitable for conveying strong abrasive and high concentration slurries in metallurgy, mining, coal, electric power, construction and other industrial sectors. It can be used in multiple stages in series.

Overview

M(R)KSH series slurry pump is a new generation of heavy-duty pump developed by our company on the basis of digesting and absorbing imported AH series products and combining our company’s more than 70 years of experience in slurry pump design and manufacturing. , and adopt advanced design methods. The slurry pump completely covers the AH series products in terms of performance, with higher efficiency and better suction performance. It has the characteristics of high efficiency and energy saving, small vibration, low noise, reliable operation, long service life and convenient maintenance.

Outlet diameter (mm): 20~650

Flow (m³/h): 10~14000

Head (m): 10~70

Material: Metal/Rubber

Product Advantages

Long lifespan

little noise

good performance

energy saving

Slurry Pumps for Mining

Slurry pumps are very critical in mining operations. It is also a strict test for the slurry pump,When the slurry pump transports objects in the mine, have you ever encountered the problem of pump cavitation or leakage? And the problem of heavy wear? For kingda slurry pump, you don’t have to worry about this problem at all, because our impeller and pump body are cast from high-chromium alloy; this material is very wear-resistant and corrosion-resistant.And Kingdapump is the veteran of this industry, we have 74 years of centrifugal slurry pump for sale technology and experience, so we can provide you with the most professional solutions for any problems.

Slurry Pumps Dredging

It is also an excellent choice for river dredging slurry pumps, as there will be a lot of sediment in the river and we will need to replace it with a rubber lining and rubber impeller.

Cement slurry pump is the most suitable pumps for the cement industry, and China is the largest market in the cement industry, followed by India, so the cement industry has specific development potential in various fields, So the Kingda team has keep in touch with customers who have been using our cement pumps.

Slurry Pumps electric power

Desulfurization pumps are generally used in metallurgy, chemical, coal, power plants and other industries. It must be corrosion-resistant, because the desulfurization pump transports fine particles, so the lining and impeller need to be corrosion-resistant.

Kingda’s desulfurization pump can meet the requirements of corrosion resistance

Company Advantage

Kingda Pump Industry was established in 1949. Now the company covers an area of more than 300 acres, with a total construction area of more than 80,000 square meters.

Kingda has strong R&D capabilities and manufacturing capabilities, and has innovated and built four platforms on the original basis: green design platform, green manufacturing platform, green test platform and green pump product life cycle analysis and management platform. A large number of advanced production equipment has been added, and a domestic first-class large-scale water pump test station has been newly built, with a test capacity of 37,000m3/h and a test head of 1,100m.

Related Products

M (R) KSL series light slurry pump

The M(R)KSL series slurry pump completely covers the original L series products in terms of performance, the products maintain the interchangeability with the L series products, and the efficiency is further optimized and improved. This series of pumps has a double pump casing structure. The inner lining and impeller can be made of replaceable wear-resistant metal or rubber, which is suitable for conveying medium, low lift, low abrasion and low concentration conditions in metallurgy, mining, coal, electric power and other industries, such as metallurgy, mining, electric power, Slurry conveying in steel mills and chemical industries.

ZGB (P) series high lift slurry pump

Double pump casing structure. It has the characteristics of high head, high efficiency, good wear resistance, stable performance and good cavitation performance. The lining and impeller materials are made of wear-resistant metal. The direction of the pump outlet can be installed and used at eight different angles at 45° intervals. The driver can choose direct drive, hydraulic coupling drive and reducer drive. Different performance conditions can also be met by cutting the impeller. The shaft seal can use packing + auxiliary impeller combination seal or mechanical seal. The bearings are lubricated with thin oil, and there are two sets of water cooling systems for bearing cooling. The direction of rotation of the pump is clockwise as viewed from the drive end. Can be connected in multiple stages.

KSHF (KSF) series foam slurry pump

According to the structure, it is divided into vertical KSF and horizontal KSHF two structures, all of which adopt double pump casing structure. The vertical KSF structure does not need to be sealed, and the material box can be lined with rubber; the horizontal KSHF structure has a small installation space and can deliver larger flow; the horizontal KSHF foam pump impeller is specially designed, the blades are extended forward, and the liquid is contacted earlier, and the suction performance is better. . The pump and driver can choose direct drive or V-belt drive. Shaft seals can be packing seals, auxiliary impeller seals or mechanical seals. The direction of rotation of the pump is clockwise as viewed from the drive end.

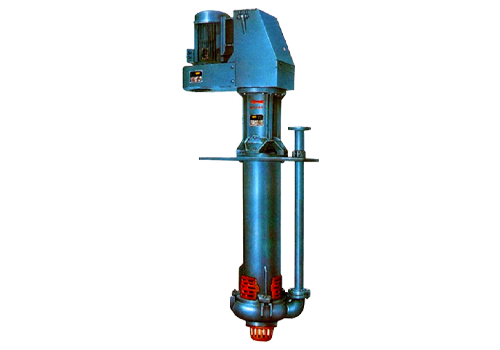

M (R) KSS series submerged slurry pump

The submerged slurry pump is vertical, axial suction, single-stage, single-suction, single-shell, centrifugal structure. The material of the overcurrent parts can be wear-resistant metal or rubber, and the length of the liquid can be selected according to the needs of the user. The structure is simple and the installation and maintenance are convenient. It is suitable for conveying submerged, abrasive, coarse particle and high-concentration slurries in metallurgy, mining, coal, electric power and other industries. Without shaft seal and shaft seal water, it can work normally even under the condition of insufficient suction.

Most reliable slurry pump manufacturer

Kingda has been developing for more than 70 years and is a leading enterprise of slurry pumps in China. One-stop service can be provided in kingda.

our service

Kingda takes “warm service, quick response, accurate judgment, and honest treatment” as its after-sales service tenet and “customer first” as its service principle.

1. A team of professional engineers, without any language barrier, to provide you with professional technical services.

2. You can tell us your plan, we can help you customize the pump you need.

3. Safe and professional shipment, with tight reinforcement of all parts to ensure that the equipment is not damaged during transport.

4. 24-hour service available 24/7 to help you solve any problems.

5. Provide online guidance

6.Parts replacement

7. Support multiple payment methods (Prepaid 30% available)

Have More Questions Please Contact Us

The Ultimate Guide to Slurry Pump

First of all, you need to determine what medium you want to transport; whether there are large particles or sediment, and what the application scenario is, such as: industrial and mining, metallurgy, power plants, rivers, chemicals, coal mines, etc. Once these are determined, you need to take into account the head, how far you need to transport. How long does it take to work, etc. Of course, if you don’t know how to choose a slurry pump, you can send your question to us, and we will have experts answer it for you free of charge.

This needs to determine the degree of wear of the pump according to your mining industry. If you are transporting large particles of stone, the wear cycle will be faster. If you are transporting mud or liquid, its wear will not be great, and the use time will be longer.

Slurry pump is a pump for conveying solid-liquid two-phase flow. Widely used in metallurgical mining, coal, electric power, chemical industry, food and other industries and sewage treatment, rivers and lakes dredging and other departments. In addition to fully meeting the requirements of working conditions, the service life of the slurry pump becomes the key.

After adopting good wear-resistant design and reasonable material selection, the service life of the pump can be effectively improved.

Your mining operation’s slurry pump is a beating heart; therefore, selecting the best one is essential to achieving optimum efficiency and profitability.

When searching for the perfect slurry pump, various elements are considered, such as the type of pump, size and capacity of your company, and series of tailor-made applications.

When there are so many alternatives available, With an overwhelming number of choices, it can take time to decide where to start. However, with a little investigation, you may locate the ideal slurry pump for your preference.

Here is a summary of your considerations when selecting a slurry pump for your mining operation.

Centrifugal Pumps

Centrifugal pumps are among the most popular in industrial and commercial applications. They work well with various liquids, including viscous slurry combinations and water and other light fluids. They utilize centrifugal force to produce a vacuum that draws fluid into the pump, and centrifugal pumps function.

The fluid is forced through the pump under pressure before exiting the other end. It can be adaptable to a wide range of flow rates and pressures. They are also relatively easy and affordable to maintain, which is another benefit. Centrifugal pumps are an excellent option for many applications as a result.

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right pump you want.