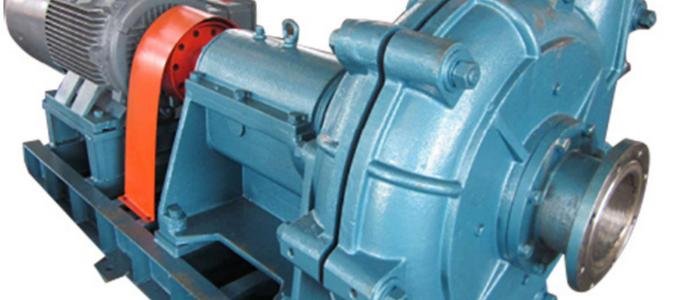

Introduction of Rubber Lined Slurry Pump

The rubber slurry pump is a horizontal, cantilevered centrifugal slurry pump. They are intended for use with highly abrasive, high-density slurry. This series of pumps can be put in multistage series.

What is a Rubber Slurry Pump?

Rubber Lined, namely the rubber parts, directly connect with slurries. They are very easily worn out because they work under the long-term impact of abrasive and corrosive slurries at high speeds. The wetted parts include the impeller, cover plate liner, frame plate liner, throat bush, frame plate liner insert, and so on.

Work in Flow of a Rubber Slurry Pump

Rubber-coated slurry pumps are also utilized in the metallurgical, mining, coal, power, building material, and other industrial sectors to handle strong abrasive, high-density slurry and low-density, high-head slurry. Typically, it is appropriate for corrosive slurry. Some larger HDR series pumps would also be utilized in ore dressing to convey fine ore or to tail with minor abrasion.

Feature of Rubber Slurry Pump

Wear-resistant rubber lined pump provides unrivaled wear resistance due to the remarkable wear resistance of rubber and the molded rubber flow sections. Its qualities are smooth operation, energy conversion, low noise, cost savings, high efficiency, ease of maintenance, and durability. The maximum pulp delivery concentration should be at most 60%.

Liners

Liners are attached, not adhesive, to the shell for a close bond and maintenance simplicity. Hard metal liners and pressure-molded elastomers are interchangeable. An elastomer has a big role of the seal surrounding all liner joints.

Impeller

Minimize backflow and sealing damage by pumping out propellers on both the front and rear coverings. Easy-to-replace propellers are comprised of solid aluminum and formed rubber. The threads on the impeller are welded in and do not necessitate inserts or nuts. Increasingly higher and high-head designs are available.

Throatbush

Tapered mating faces allow for exact positive alignment during assembly and straightforward removal, reducing wear and simplifying maintenance.

Casing

Cast or ductile iron casing halves with external reinforcing ribs protect the worn liners and enable high working pressures.

Pump frame

The “cartridge” shaft and bearing assembly are held in place by a robust and one-piece casting. A few through bolts secure the pump case to the frame. In a handy location below the bearing housing, an effortless way of external impeller adjustment is provided.

Shaft seal

Mechanical seal, packing seal, centrifugal seal

Application of Rubber

Rubber slurry pump can handle corrosive slurry or fluids containing solid materials, outperforming metal and other pumps.

Beneficiation-metallurgy plant

Hydro cyclone feeding in the ore processing circuit (includes the very first stage of classification) hydro cyclone); pump delivery, concentrations, sediments, and unfinished goods concentration and filtering; all types of slurry pump delivery.

Power plant

Rear waste, sludge, and coal ash delivery

Sand and gravel plant

On the other hand, sandstone movement, industrial gravel and water system, and all sorts of classification and dewatering equipment movement, industrial gravel and water system, and all sorts of classification and dewatering equipment, on the other hand, have extremely high wear resistance.

Chemical plant

They treat chemical liquid, acid or base, slurry, and wastewater at low and medium temperatures.

Water conservancy project

Damming, silt displacement in the bed, sand and gravel classification, and so on.

Paper mill

Treatment of sludge, pulping the slurry, and other water industries.

Ceramic and glass plant

porcelain clay and gravel transportation, hydro cyclone supply, and wastewater treatment.

Steel Plant

The supply of mud, skin oxide, and corrosive liquid. We should provide special instructions to us if with oils and chemicals.

Advantages of Rubber Slurry Pump

These slurry pumps can handle more than simply sand. They are incredibly effective at pumping slurry, gravel, concrete, mud, slush, and other materials.

A rubber slurry pump has several advantages:

Strong design

The rubber liner is made of unique materials and is more corrosion and abrasion-resistant.

Perfect for slurry pumping

Only rubber liner pumps have the strength and corrosion resistance needed to make an effective slurry pump.

Repairable

Rubber-lined pumps are repairable; replace the liners.

Discharge port

can be positioned at 45-degree intervals and directed to up to eight different configurations based on your demands

Robust design

Rubber liners are composed of unique materials and are more corrosion and wear-resistant than their competitors.

Ideal for slurry pumps

Rubber-lined pumps are the only ones that combine strength and corrosion resistance to make a high-quality slurry pump.

Other advantages:

- A two-part elastomeric liner minimizes casing wear caused by abrasive fluids.

- An elastomeric is almost impeller wear. Furthermore, the adjustable screw on the bearing housing makes it easier to center the impeller within the casing.

- A split casing design allows for easy access to pump bearings.

- Pump frames have been changed to save 10% on overall pump weight. Despite the weight savings, the modification increased pump strength to ensure long bearing life.

- Ideal for seawater, freshwater, drilling mud, and various industrial applications such as construction, mine dewatering, and many others.

Wear-resistant Rubber Slurry Pump

Before beginning the pump, the pump body and inlet line are filled with liquid and driven by a motor. The impeller causes the fluid between the vanes to revolve together with high-speed rotation. The liquid is flung to the outer edge of the impeller with enhanced kinetic energy due to the influence of centrifugal force.

After entering the pumping shell, the stream movement effectively decreases as the control element in the vane pumping cover is progressively stretched, converting some of the kinetic energy into static energy. The elevated stream is released along the outlet. At the same time, the impeller center creates a vacuum in which the liquid is ejected. Because the pressure on the liquid level is more significant than that on the impeller center, the fluid in the suction pipe will flow into the pump due to the pressure differential. The liquid is continuously sucked and extruded due to the steady rotation of the impeller.

What is High Chrome Slurry Pump

High chrome alloy is a family of white cast irons that are resistant to erosion and corrosion and are designed for use in corrosive slurry pumps. These are multi-phase materials with strong carbides (to withstand decay and wear) and a stainless ferrous matrix. The carbide phase characteristics and the ferrous matrix’s composition can be tailored to optimize the alloy’s performance in various slurries.

Application of High Chrome Slurry Pump

High chromium can be used in a wide range of mildly corrosive slurries (usually down to pH 4) and is notably erosive. Other uses where it performs well include seawater slurries (in dredging) and plant water in distant places where hypersaline water from bores is employed.

High chrome is designed for slurries containing moderate sulfur and nitric acid solutions. FGD is the most general application, with chloride levels reaching 50,000 ppm depending on pH; additional applications include mine drainage, where dissolved solids can cause severe deterioration. Solids percentages are typically less than 20% by mass.

Because High chrome contains less carbon than High chrome, there is less chrome in the cemented stage and more chromite in the polymer. Thus, the ferrous matrix of High chrome A4 contains more dissolved chromium than High chrome’s. As a result, in mildly acidic situations, High chrome has a very more substantial component of corrosion resistance than High chrome.

Rubber Lined Vs. High Chrome

Various MOC (materials of construction) alternatives are necessary for industrial processes requiring slurry pumps to achieve a good wear life with abrasive and often corrosive fluids.

Manufacturers often provide rubber or high chrome-hardened steel wear components as standard, with more exotic materials available for more corrosive applications. Slurry pump applications use rubber and metal, and an experienced pump supplier will collaborate with the client to determine the optimal material for the application.

However, there needs to bclearication about which material is the best choice, and a change in duty point can severely impact worn component life and pump reliability.

Pumps with metal (maximum chrome hardened) or rubber liner and propeller are offered.

Some applications, such as a metal impeller with rubber liners, call for a hybrid technique. One example is when the desired discharge head requires the pump to operate at a speed that is too rapid for a rubber impeller. A metal impeller with rubber liners is employed in these applications.

Pumps include replaceable rubber/metal liners, allowing maximum site flexibility if a shift in duty or fluid qualities necessitates a change in impeller or liner material.

In summary, rubber wear parts are the best choice for pump slurries with small, smooth, and lightweight particles that “bounce” off the rubber wear parts since they are less expensive and lighter. However, high chrome metal wear components are often recommended in applications with higher temperatures, pump speeds, or slurry characteristics such as sharp mineral particles.

If you have questions about the Rubber Slurry Pump, you can contact us anytime or call +86 18633935649 for faster transactions, and our senior engineers will answer you at any time.