A Guide for Progressive Cavity Slurry Pump

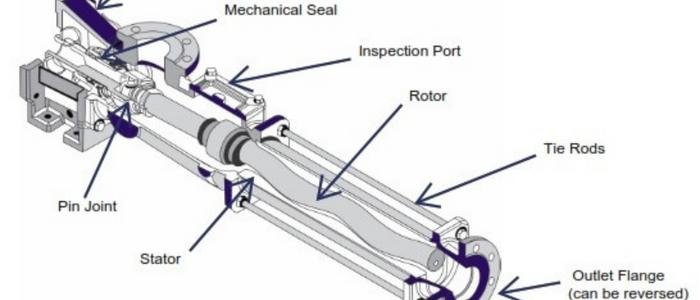

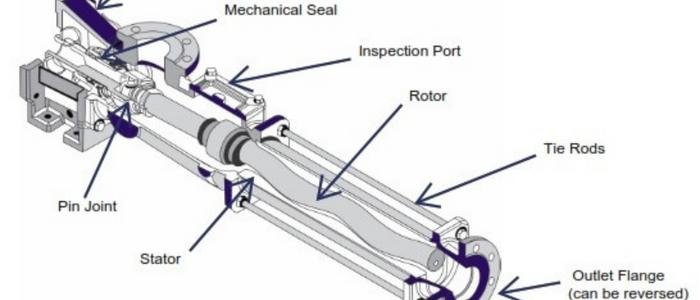

What is Progressive Cavity Slurry Pump? A PC pump or progressive cavity slurry pump is a type of positive displacement

What is Progressive Cavity Slurry Pump? A PC pump or progressive cavity slurry pump is a type of positive displacement

The Kingda Pump Industry was founded in 1949. Today, the business occupies a total construction area of more than 80,000

What is Ceramic Slurry Pump? Ceramic pump parts are made of Silicon Nitride Bonded Silicon Carbide. They are designed for

The pump has all of the benefits of standard horizontal centrifugal slurry pumps, such as durable wear flow parts, suitable

Sand and sludge are rarely mentioned in “pleasant” conversations. Any of these words conjures up images of filthy muck, bacteria,

What is a Heavy Duty Slurry Pump? The term “heavy-duty pumps” refers to submersible pumps that must meet strict standards

An abrasive slurry combines abrasive material (for example, silicon carbide and boron carbide) in water or oil. Vibration can cause

The slurry circulating pump is the cornerstone of the desulfurization equipment. It is located next to the absorption tower. Its

High-Head Slurry Pump: What is It? The High Head Slurry Pump is a heavy-duty, cutting-edge slurry pump that move abrasive

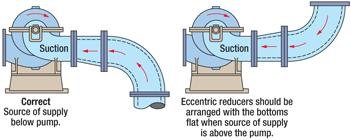

The Slurry pump suction piping is an often forgotten component of an effective pump system, yet it is critical in