Kingda will be participating in the 2026 Asia Pacific Maritime

Dates:25 – 27 March 2026 Address: Halls F, B29, Marina Bay Sands, Singapore We are proud to announce that Kingda

Dates:25 – 27 March 2026 Address: Halls F, B29, Marina Bay Sands, Singapore We are proud to announce that Kingda

What is a pump failure? Pump failure refers to a pump’s inability to deliver liquids as initially designed or to

Centrifugal pumps were first created by French physicist Denis Papin in 1689 and without a doubt that centrifugal pumps play

As early as the ancient Egyptian period, people used simple tools to remove sediments and debris from the bottom of

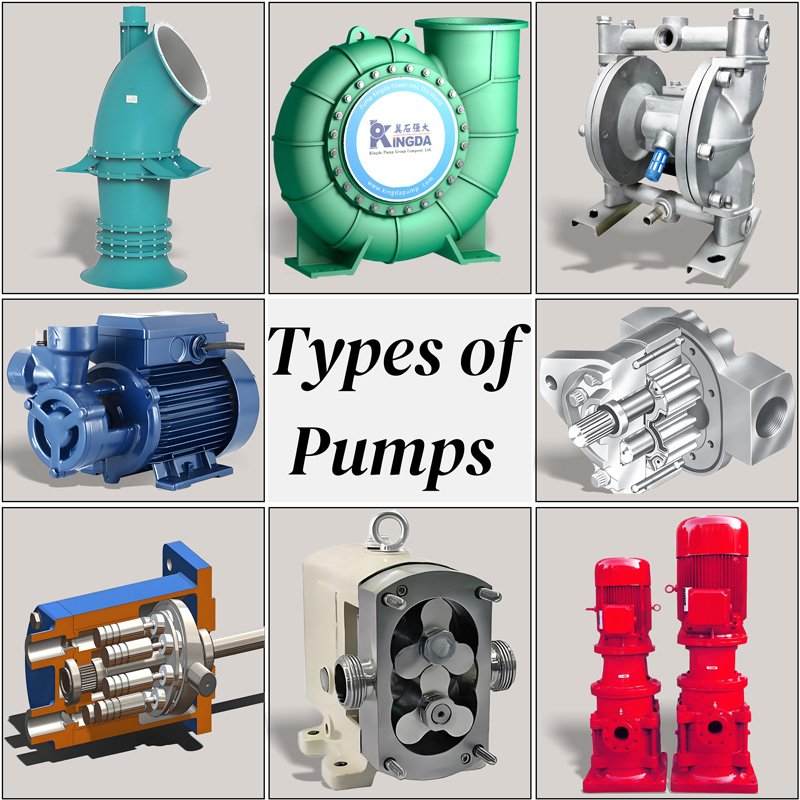

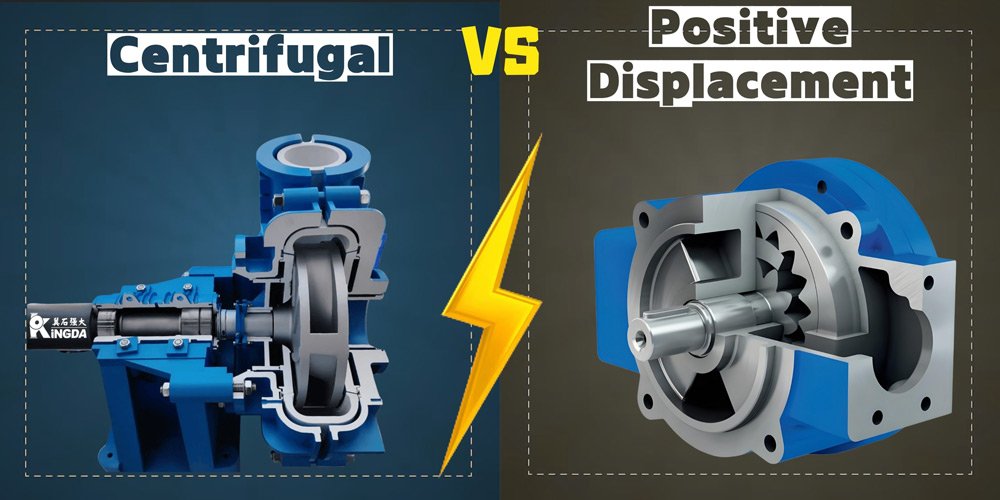

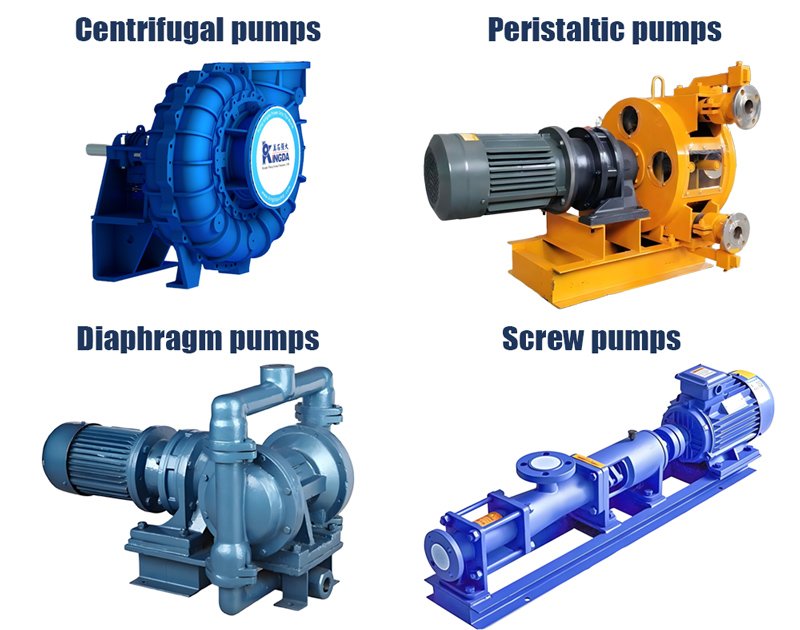

There are two main types of pumps: Dynamic Pumps and Positive Displacement Pumps, i will break down what follows by

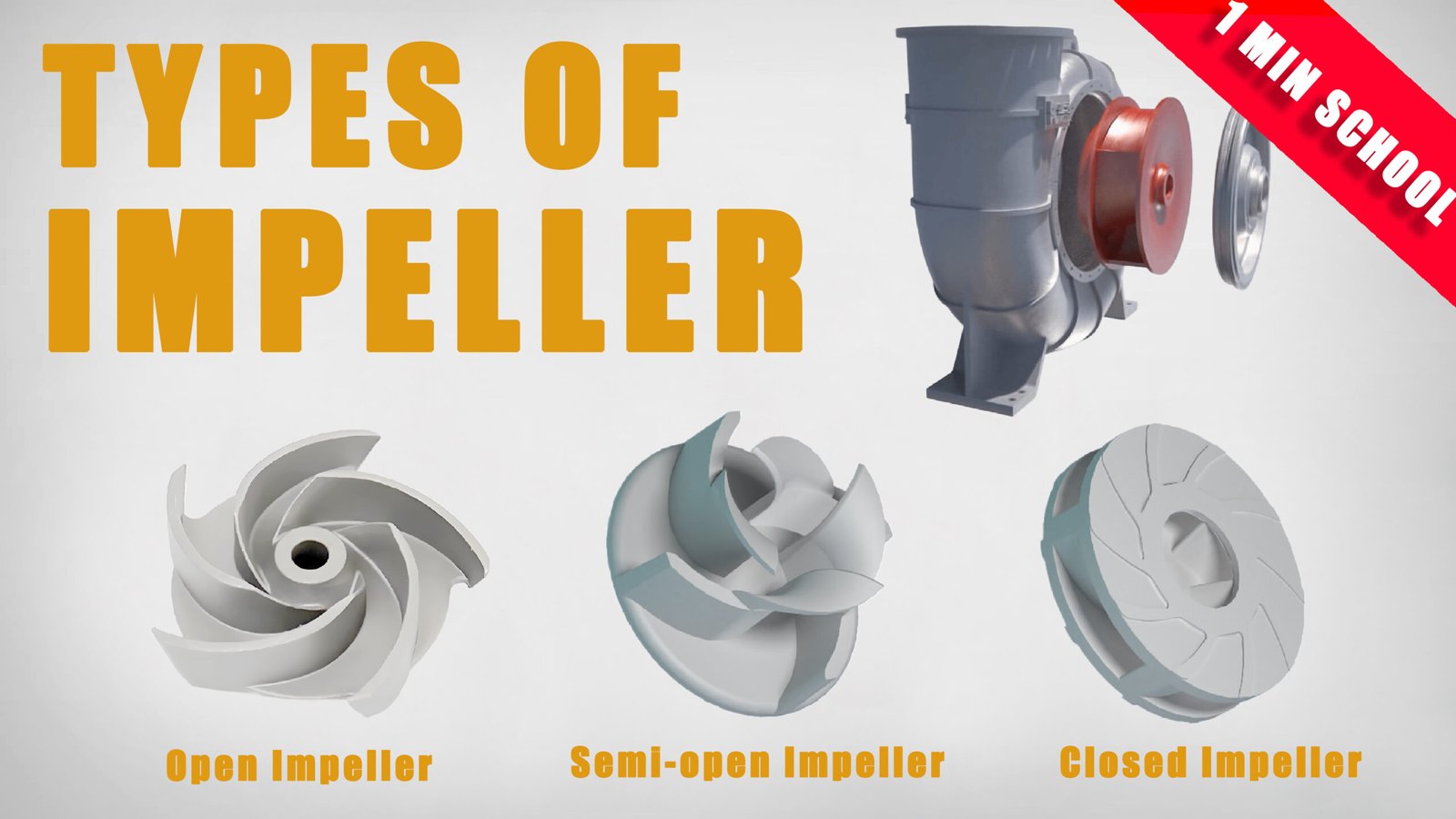

Infographic | Impeller Types Before learning about all pump impeller types, I invite you to review the infographic below. It’s

Slurries are specialized compounds found in various processing industries, including sanitary sectors like mining, aggregates, mineral processing, dredging, tunneling, and

Centrifugal pumps are one of the most widely used pump types today. This article will detail centrifugal pump spare parts

Centrifugal pumps, due to their simple structure and stability, have gained increasing recognition and use from various enterprises. With advancements

When selecting pumps, performing routine maintenance, or learning about pumps, comparisons are inevitable: centrifugal vs. positive displacement pumps. What exactly

🕒 Dates: September 23-26, 2025 📍 Address: 64/1, Peterburgskoye Shosse, St. Petersburg 🔸 Booth: Hall H4 Stand 432 Kingda will

Kingda participated in the 23rd International Mining & Mineral Recovery Exhibition in Indonesia from September 17th to 20th, showcasing its

🕒 Dates: September 22-26, 2025 📍 Address: Cerro Juli Convention Center 🔸 Booth: Pavilion 5, No. 786 Kingda will be

The existence of sewage pump makes it possible to transport solid particle slurry, which greatly improves the efficiency of our

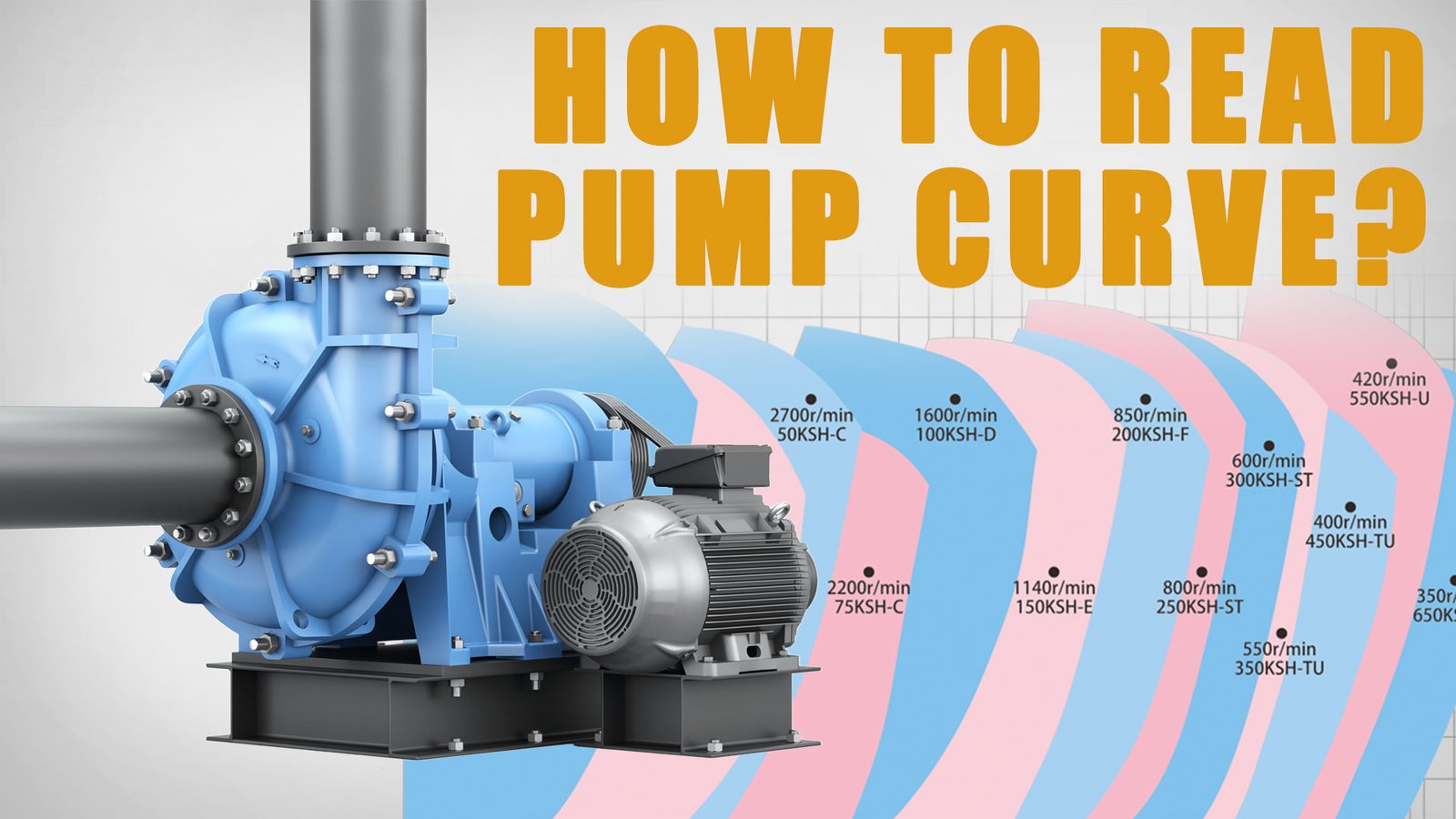

Pump curve not only serve as a guide for engineers when designing fluid transport solutions, but also provide information for

Slurry Pump Meaning A slurry pump is a centrifugal pump. Manufacturers typically use highly wear-resistant materials for the impeller and

What is Cavitation in Pump? Pump cavitation refers to the situation where when the pressure on the liquid in the

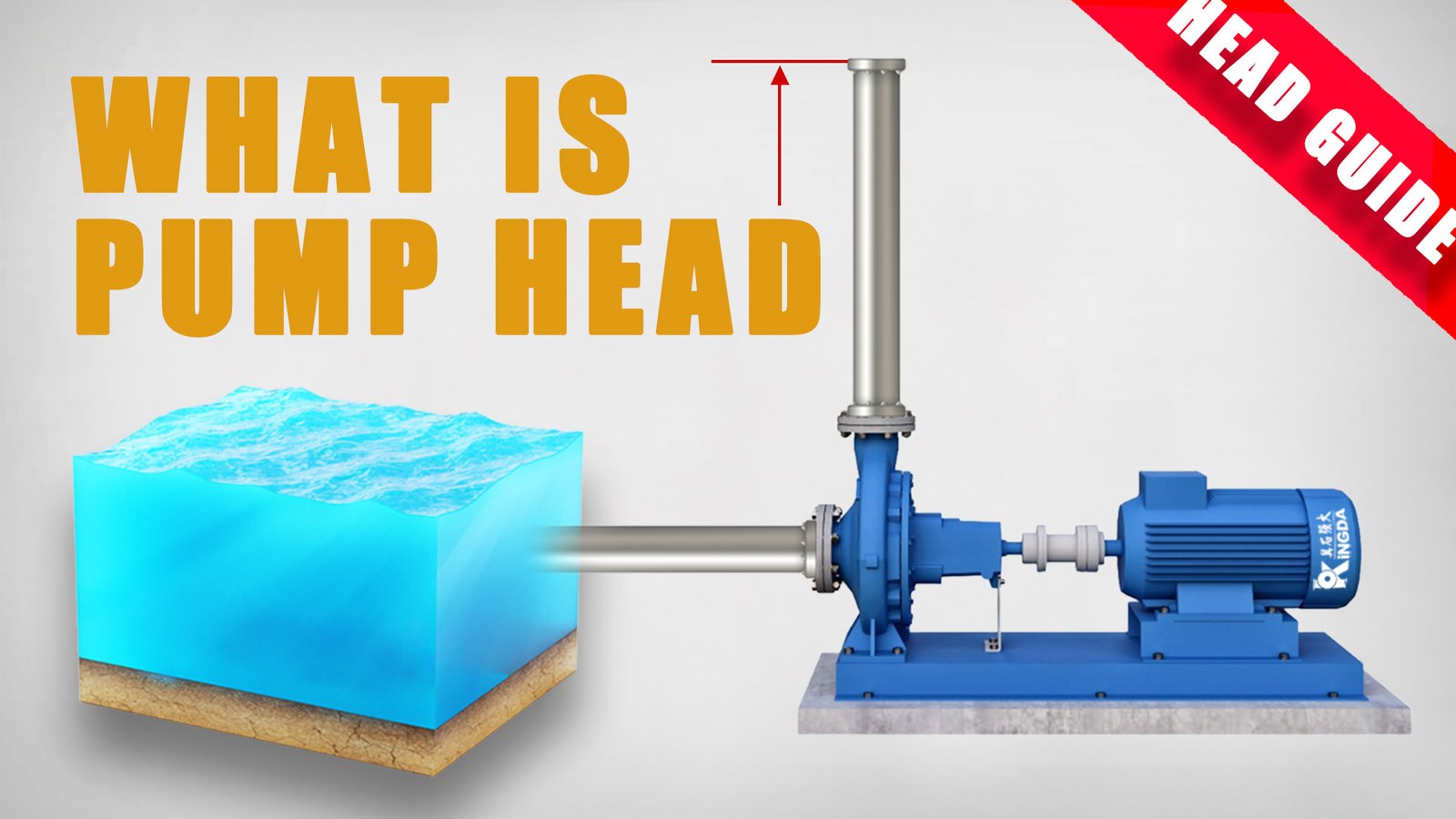

When we select a pump, we will learn about the pump head. Maybe you will be confused about this, don’t

Are you worried about choosing the right submersible pump, this guide will comprehensively explain the knowledge points about submersible pumps.

What is Submersible Pump? Submersible pump work in water, so they can transport fluids below the liquid surface to above

In October 15, 2024, Kingda Pump Group made a grand appearance at the China International Mining Conference, with booth number

Kingda Pump Group is excited to announce that we’ll be attending MINExpo 2024, happening from September 24-26 in Las Vegas.

Kingda Pump Group will be participating in the Iran MINEX 2024 “ Iran’s Mines & Mining Industries Exhibition“ from September

From September 17 to 19, 2024, Kingda Pump Group will participate in the International Road and Heavy Construction Machinery Exhibition

From September 11 to 13, 2024, Kingda Pump Group will participate in the prestigious Lima Mining Fair (ExpoMina Peru 2024),

On June 3rd, local time, the 20th Chile North International Mining Exhibition was held as scheduled in 2024. On the

List of Green Manufacturing for the year 2023 Recently, the Ministry of Industry and Information Technology of the People’s Republic

In an effort to enhance workers’ awareness of fire safety, disseminate fire prevention knowledge, and cultivate employees’ habits and emergency

As a leading enterprise in the slurry pump industry, Kingda Pump Group specializes in the technical research and product design

At Kingda Pump Group Company Ltd., we find ourselves pausing in gratitude on this special Thanksgiving day. In the spirit

The 2023 Dubai International Mining Exhibition is set to open its doors on November 21–22, and Kingda Pump Group, a

🌕🇨🇳 Join us for a festive celebration as Kingda Pump Industry extends warm wishes for both the Mid-Autumn Festival and

Leading the Way in Fluid Transfer Innovation On September 20th, the grand opening of the Kazakhstan Construction Machinery and Mining

Mining and Metals Central Asia 2023 Slurry Transfer Pump Manufacturer September 20-22, Almaty Mining Expo, Booth Number: 11-310 Dear Mining

A submersible sludge pump plays an important role in all kinds of industries that require pumping of liquids with high

Manufacturers are always considering the product’s usefulness and performance aside from addressing the marketplace’s demand. In the real world,

Slurry pumps of the AH, M, and HH series are horizontal pumps. Slurry transportation is critical to the success of

Kingda Pump Group Co., Ltd. will participate in the EXPOMIN 2023 Chile International Mining Exhibition held in Santiago on April

What are the Causes of Damage to the Slurry Pump? Reverse Rotation This occurs when the slurry pump‘s wiring is

High-Head (hh) Slurry Pump is heavy-duty slurry pumps designed with cutting-edge technology to transport high-density slurries and abrasives in heavy

Understanding Pump Capacity Pumps are classified into three types: reciprocating, diaphragm, and centrifugal. Because of their durability and performance, centrifugal

What is a Slurry Dewatering Pump? A slurry dewatering pump is used to pump liquid with solid particles. Submersible slurry

An electric submerged slurry pump is used in the dredging, quarrying, and mining industries to move sand and sludge. All

When looking for the best slurry pump, will you consider the need for heavy-duty operations? Kingda offers something of value.

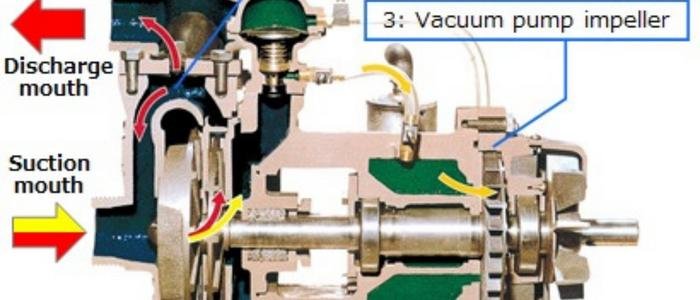

What is a Self-priming Slurry Pump? Continuous suction and long-term use are features of industrial-strength self-priming slurry pump for transporting

A polyurethane slurry pump is a fluid machine that provides fluid energy. Some authors call pumps “energy-absorbing machines” because they

Hose pumps, also called peristaltic pumps, are a great way to move a lot of liquids. These pumps are strong

Most of the time, the pump will be somewhere between the point of suction and the point of discharge. The

Water is the most important thing we require for survival. People who live in cities, suburbs, or even on the

Simply put, a mechanical seal is a way to keep fluid inside a container (usually a pump, mixer, etc.) where

A fluid machine that adds energy to a fluid is called a pump. Some authors call pumps “energy-absorbing devices” because

A booster pump may be required to improve output when pushing slurry or viscous material across long distances. A pump

What is a Screw Slurry Pump? Screw slurry pump transfer liquids, solids, or liquid-solid mixtures from one location to another.

A special kind of pump called a “slurry pump” handles the slurry. Slurry pumps are made of stronger materials and

Introduction of Rubber Lined Slurry Pump The rubber slurry pump is a horizontal, cantilevered centrifugal slurry pump. They are intended

A chemical slurry pump requires a liquid to keep it moving. They are frequently used when a corrosive or abrasive

Slurry pumps deal with liquids that contain solids, such as sewage, coal slurry, and ore slurry. Typically, when solids damage

Any plant in the aggregate industry can significantly benefit from knowing what kind of Portable slurry pump to utilize. The

In industrial or commercial uses, pneumatic systems mostly use pushed gas or air to move and are often powered by

We’ve discussed the distinctions, but how well do you know the difference between centrifugal and positive displacement pumps? Let’s look

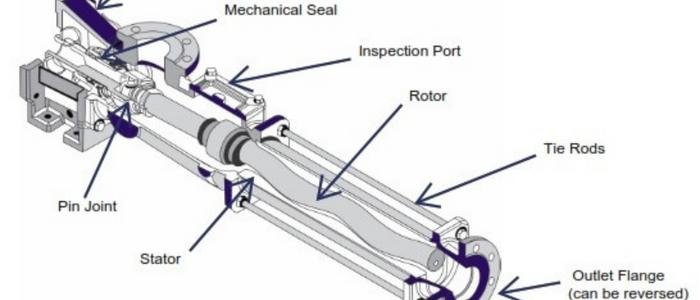

What is Progressive Cavity Slurry Pump? A PC pump or progressive cavity slurry pump is a type of positive displacement

The Kingda Pump Industry was founded in 1949. Today, the business occupies a total construction area of more than 80,000

What is Ceramic Slurry Pump? Ceramic pump parts are made of Silicon Nitride Bonded Silicon Carbide. They are designed for

The pump has all of the benefits of standard horizontal centrifugal slurry pumps, such as durable wear flow parts, suitable

Sand and sludge are rarely mentioned in “pleasant” conversations. Any of these words conjures up images of filthy muck, bacteria,

What is a Heavy Duty Slurry Pump? The term “heavy-duty pumps” refers to submersible pumps that must meet strict standards

An abrasive slurry combines abrasive material (for example, silicon carbide and boron carbide) in water or oil. Vibration can cause

The slurry circulating pump is the cornerstone of the desulfurization equipment. It is located next to the absorption tower. Its

High-Head Slurry Pump: What is It? The High Head Slurry Pump is a heavy-duty, cutting-edge slurry pump that move abrasive

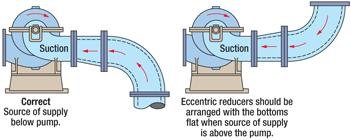

The Slurry pump suction piping is an often forgotten component of an effective pump system, yet it is critical in

Discover how Kingda’s submersible slurry pump will solve your problem. These are heavy-duty pumps that are ideal for pumping a

Slurries are special substances that are used in many types of processing, including in clean industries like the production of

China slurry pump development has undergone introduction, absorption, and autonomous action. Chinese pump technology was underdeveloped in the early years

Mining and aggregate slurry handling is a strenuous activity that can significantly influence plant productivity and efficiency. As global demand

Finding the best slurry pump can be risky and challenging, especially for cement. Choosing a cement slurry pump requires careful

Please take this into account before making your purchase, here are some things you need to be aware of when

Slurry pumps are frequently used to transport fluids such as slime water, flowing water, coal slurry, heavy medium suspension, and

Ash Slurry Pumps are commonly used in mining, sand, dredging, electric power, metallurgy, coal, environmental production, and other industries to

Diaphragm pumps are better suited for pumping thicker liquids like sewage and mud. The most popular type of diaphragm pump

If you think of the best Hydraulic Slurry Pump for a specific application, you will be confused, and it is

One of the most widely used pumps for moving corrosive and abrasive materials is the industrial slurry pump. These pumps

Slurry pumps, and centrifugal pumps, move fluid mixtures containing solid materials, such as mud, ore slurry, ore sand, etc. Vertical

Slurry pumps are different from regular water pumps in a few key ways. Slurry pumps are designed to handle liquids

Slurry pumps are used widely throughout the beneficiation section of the mining industry, where most plants utilize wet separation systems.

A slurry pump is a type of centrifugal or lobe Pump that increases the pressure of a liquid and solid particle

Slurry pumps handle fluids containing solids, such as ore slurry, coal slurry, or sewage. They are typically used in applications

Slurry pumps are a form of centrifugal pumps. In its basic concept, a slurry pump is a type of machine that

The slurry pump needs to be connected to the motor to generate kinetic energy to transport the material out. Coupling

Finding the perfect slurry pump can be a very risky and daunting task. There are many things to think about

Small slurry pumps are effective in almost any application. They are lightweight, easy to use and transport, and they can

Slurry is one of the most challenging fluids to move. It’s highly abrasive, thick, sometimes corrosive, and contains a high

Kingda Focused On OEM Solutions of Heavy Duty Slurry Pump Hebei Kingda Group is one of China’s largest professional manufacturers

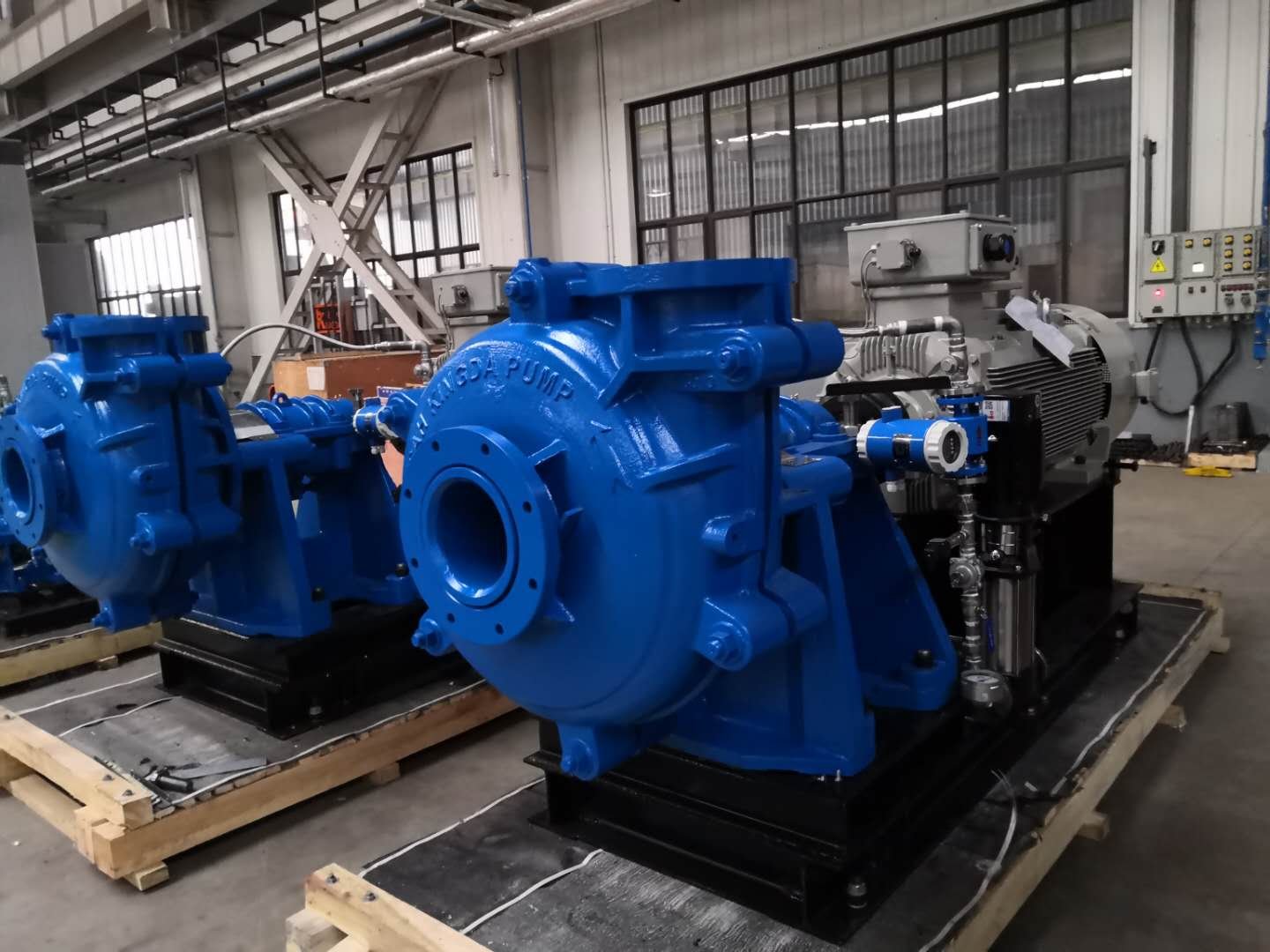

In order to better control product quality, each Kingda pump has undergone numerous tests. These tests run through the entire

Why we need Slurry Pumps in the Mining IndustrySlurry pump is widely used in mining industry, no matter iron, copper,

Metallurgy, namely the the process of separating and concentrating raw materials, plays a more and more important role in the